TRAINING

Field Balancing (In-place Balancing) Training

When the center of rotation is not equal to the center of mass, you have an unbalance condition. Shafts, Bearings, Bases & more suffer when unbalance is present.

When your machine is shaking and you are tired of replacing bearings with low hours, balance your machinery in place and eliminate one of the most common sources of early bearing failure.

High levels of vibration can destroy bearings, cause hydraulic lines to leak or break and cause support bolts to come loose or back out. This is where best practices in single plane balancing, precision balancing, and dual plane balancing can keep your operation running smoothly.

Field Balancing needs we commonly encounter

Unbalance

We have found that 85% of high vibration problems in ID fans come from unbalanced rotors.

The Solution

Field balancing will extend the life of your bearings and fix your problem with little downtime. Shop balancing is another method, however, the rotor is taken out of the head and sent to a shop. This causes longer downtime, usually by days, and generally costs more.

Why field balancing can improve your business and create positive ROI

The primary reason for field balancing is to reduce vibration. Excessive vibration can cause:

- Shafts to break

- Bearing failure

- Pipe stress or leaks

- Hydraulic line breaks

- Bolts to loosen or back out of their holes

Field balancing can eliminate many of these problems, and in some cases, it is the only way to solve them.

Field balancing can be performed on rotating machinery that cannot be easily moved, such as:

- Pumps

- Motors

- Compressors

- Fans

- Blowers

- Generators

- Gearboxes

- Pulleys

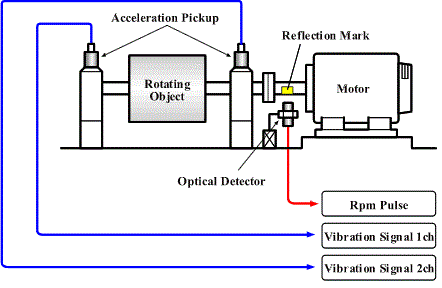

Field balancing is a specialized skill that requires the use of special tools and equipment. Many companies choose to have their employees attend field balancing training courses so that they can learn how to properly balance their machinery in-place.

Our Field Balancing Training Course covers the following topics:

- How to identify unbalance

- How to measure unbalance

- How to correct unbalance

- How to perform Field Balancing

After completing a field balancing training course, employees should be able to:

- Understand the basics of rotational dynamics

- Identify the different types of unbalance

- Use basic measuring tools to quantify unbalance

- Use Field Balancing techniques to correct unbalance

Field balancing certification exams

Our field balancing training courses will culminate in a certification exam. Employees who pass the exam will receive a certificate that they can use to show current or potential employers that they have the skills and knowledge necessary to perform field balancing properly.

Field Balancing Course by Failure Prevention Associates

Learn how to perform balancing without removing the rotor. It is as easy as getting your tires balanced, but with field balancing, you do not have to move the tire off the car.

Our two-day class will provide you with the understanding and practical skills to safely perform balancing of rotating equipment. Learn how to tell if equipment resonance is causing the rotor to “look” imbalanced.

Learn where to add or subtract weight to achieve a smooth rotation and bring your equipment back into spec.

ROTOR BALANCING ON-SITE COURSE

Sometimes, the need for field balancing goes beyond the classroom. At FPA we can come to your job site to provide training and custom preventative maintenance programs for your staff. Contact us for custom pricing and consultation information.