INTERESTED IN OUR PRODUCTS, TOOLS, AND SERVICES…

Hire us to come on-site. Contact Us Today!

For immediate response, please contact Lakan Taylor by email.

services

services

We provide vibration analysis courses that will allow you and your teams to achieve up to a level 2 certification in vibration analysis.

Our vibration analysis training is based on the ISO 18436-2 standards and covers both theoretical and practical concepts.

The course is designed for those who have little to no experience in vibration analysis as well as those who want to brush up on their skills.

The course covers the following topics:

- Condition monitoring program

- Review of basic vibration analysis science

- Review basic machine faults

- Recognition of poor data

- Waveform and Spectrum Graph analysis

- Phase analysis for field applications:

- Unbalance, Eccentricity, Bent Shaft, Misalignment, Soft Foot, Resonance

- Introduction to Field Balancing

- Hands-on Workshop practicing phase analysis techniques

- Vibration analysis case studies

- Vibration Measurement, Data Collection & Analysis Practical

- And More!

Visual Vibration™

Turn your cell phone video into a visual vibration model. Now you can know what is going on sooner than any other time in history. You can record your own video, upload it to our site, and we will analyze and reply back with a Visual Vibration video with an assessment.

Create an animated model from just from stable cell phone video that shows how your machine or structure is moving. This modeling and vibration data collection used to take weeks and cost $40k, $60k or more.

Electric Motor Evaluation

Best practice to rapidly evaluate your motors, generators and transformers.

We use best practices for analysis of electric motor/generators (stator windings, rotor, air gap, insulation, power quality and power circuit) and transformers.

We can help you find motor faults before they trip breakers or worse.

products

products

IRISS -Safe-Connect Thermochromic Solutions

The Safe-Connect product line from IRISS offers the advantage of thermochromic science for visual indication of asset health. Thermochromic components in these products causes a color change based on temperature ranges, providing 24/7 safety monitoring to give a predictive warning on overheated equipment. The permanent quality of the change is able to highlight issues in straight and non-continuous load applications, protecting against electrical fire or equipment failure.

tools

All vibration monitoring systems need sensors, cables and mounting pads. CTC offers an unconditional lifetime guarantee on all of its products. Junction boxes help speed data collection with single-point access to multiple sensor locations.

Permanently installed measurement systems monitor production critical machines around the clock. Ideal for machine trains with high downtime costs, high failure probabilities, rapid damage progression, environmental or safety risks.

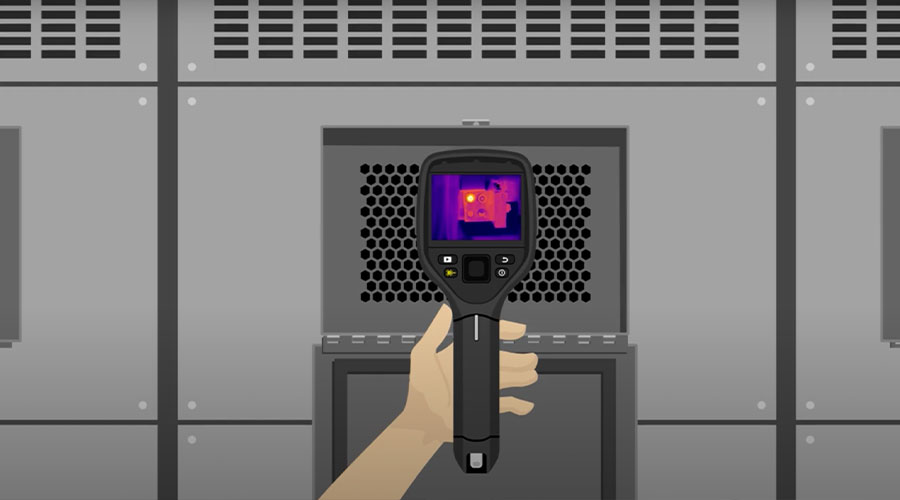

Thermal imaging can see trouble spots that are not otherwise able to be detected.

Thermal imaging and thermography uses our best practice analysis of electrical systems, switches, transformers, etc.

tools

about

about

At Failure Prevention Associates we help industries run better by preventing failures through improving people, processes, and asset management. We do this by evaluating and implementing condition monitoring programs. We will help you and your staff refine and execute predictive maintenance techniques into your plant. Start today.

Who We Are

Failure Prevention Associates, LLC. (FPA) is comprised of staff certified in Vibration Analysis, Thermographics, Ultrasound Inspection, Electric Motor Testing, Field Balancing, Laser Alignment, and Reliability Centered Maintenance Practice.

Our staff have the “in-the-trenches” experience that comes from working in plants and repairing machinery. That experience, combined with their training and certifications, allows FPA staff to rapidly analyze and report what condition based problems are present in your critical equipment.

We have also developed unique training programs based on our experience training and implementing a large number and variety of Reliability Centered maintenance programs so that the technicians we train get hands-on experience and practice with all of their tools and with discovering and repairing failure conditions.

Our certified experts also have the experience to work with your administrators and executives to implement your full programs.

Whether you are looking to optimize your maintenance to save money and increase efficiency, train your staff or implement a full program, our experts can deliver what you need to maximize your uptime and eliminate downtime, leading to better profits, and keeping your business in the black.

Around the clock, around the world, we come to you.