SERVICES

Electric Motor Evaluation

Services

Electric Motors Evaluation using PdMA

Best practice to rapidly evaluate your motors, generators, and transformers.

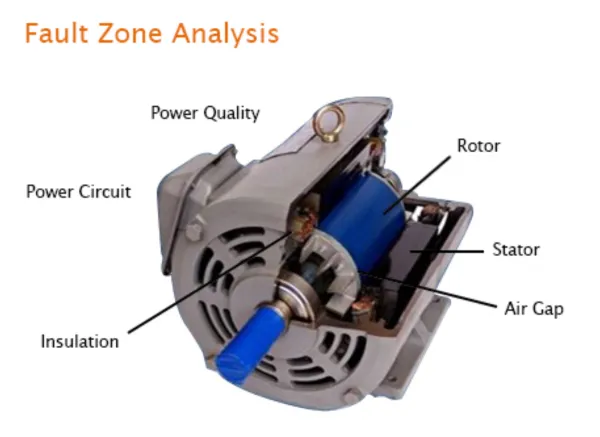

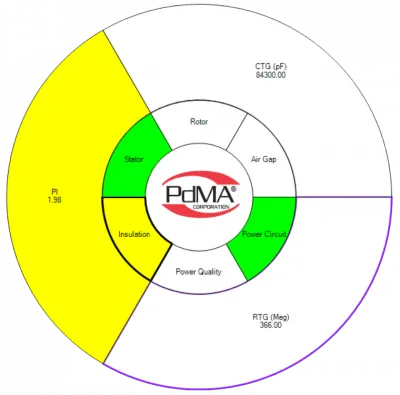

We use best practices for the analysis of electric motors/generators (stator windings, rotor, air gap, insulation, power quality, and power circuit) and transformers.

We can help you find motor faults before they trip breakers or worse.

Electric Motor Testing Basics

An electric motor is an electrical machine that converts electrical energy into mechanical energy. The reverse of this would be the conversion of mechanical energy into electrical energy which is done by an electric generator.

How do electric motors work?

Electric motors work by using alternating current (AC) or direct current (DC) electric power to produce rotational force. This rotational force is what powers electric motors.

There are three main components to an electric motor: the stator, rotor, and commutator.

- The stator is the stationary part of the electric motor. It houses the electric motor’s field coils and generally contains either permanent magnets or electromagnets.

- The rotor is the rotating part of the electric motor. It contains the electric motor’s armature windings.

- The commutator is a switch that reverses the direction of current flow in the electric motor’s armature windings.

Keeping your electric motors running smoothly is important to the overall efficiency of your operation. electric motor evaluation can help you identify potential problems before they cause downtime, and improve overall motor performance and efficiency. At FPA we provide the following services related to Electric Motor Testing:

- Performing Conditional Maintenance

- Providing training in electric motor testing for maintenance teams & operators

- Condition Monitoring Programs

- Visual Vibration & Vibration Analysis

At Failure Prevention we apply the following best practices in Electric Motor Evaluation to keep your business running.

POWER CIRCUIT TESTING

The power circuit refers to all of the conductors and connections that exist from the point at which the testing starts through to the connections at the motor. It can include circuit breakers, fuses, contactors, overloads, disconnects, and lug connections. Research on industrial power distribution systems has shown that connectors and conductors are the sources of 46% of the faults reducing motor efficiency.

The MCEMAX® powered by MCEGold® provides a unique advantage to test the power circuit and all the associated components. Many times a motor, although initially in perfect health, is installed into a faulty power circuit. This causes problems like voltage imbalances, current imbalances, sequence currents, etc. As these problems become more severe, the horsepower rating of the motor drops, causing temperatures to increase and insulation damage to occur. It is important to evaluate the resistance and inductance of a motor circuit once a motor is installed for service. High imbalances of voltage, current, resistance, or inductance could indicate problems with the motor or power circuit. Identifying minor imbalances early will eliminate catastrophic failures and headaches later.

POWER QUALITY

The Power Quality fault zone focuses on the condition of the voltage and current in a motor’s branch circuit. Poor power quality can greatly affect the operation and health of an electric motor. During operation, several stresses are brought to bear upon key components of the motor. Variances or distortions in the voltage powering motor result in increasing both thermal and electrical stresses to the stator windings and in some cases components of the rotor.

MCEMAX® powered by MCEGold® provides you with many ways to analyze and evaluate your power quality. MCEGold® not only provides you with a snapshot of your power quality, it also allows you to evaluate the individual voltage and current harmonics out to the 50th harmonic.

ROTOR

Rotor health refers to the integrity of the rotor bars, rotor laminations, and end rings of the squirrel cage induction motors. In a joint study by EPRI and General Electric, rotor defects were estimated to be responsible for approximately 10% of motor failures. The rotor, although responsible for only a small percentage of the motor problems, can influence other fault zones to fail.

MCE® motor circuit analysis uses inductance measurements taken from each phase of the stator windings and compares them at different rotor positions to further define the condition of the rotor. Advanced systems like EMAX provide simultaneous analysis of all three phases in its current signature analysis, which is an advantage over-analyzing a single current. Using inductance measurements, current analysis, and other rotor testing technology provides the user with the ability to see very early changes in the magnetic signature of the rotor.

INSULATION

The Insulation fault zone refers to the condition of the insulation between the windings and ground. For electrical equipment to operate properly and safely, it is important that the flow of electricity takes place along well-defined paths or circuits and that it was not leaking from one path to another. Deterioration of the insulation systems can result in an unsafe situation for personnel exposed to the leakage current.

The MCE® technology allows you to identify potential problems with the insulation by recognizing adverse trends in resistance to ground. After conducting a baseline test, all subsequent tests are compared to the initial data with significant changes in value highlighted in yellow for caution or red for alarm.

STATOR

The stator fault zone is often considered one of the most controversial fault zones due to the significant challenge of early fault detection and the prevention of motor failure surrounding the stator windings. Stator windings are the heart of the motor, producing the rotating magnetic field, induction current, and torque to turn the rotor and shaft. This challenge is further intensified in higher voltage machines, where the fault-to-failure time frame becomes much shorter. The stator fault zone is identified as the health and quality of the insulation between the turns, coils, and phases within the slots and end turn of the electric motor.

Turn-to-turn or phase-to-phase shorts can be catastrophic to the motor and not necessarily be detected by the standard megohmmeter. Excessive inductive imbalance, resistive imbalance, vibration, partial discharge, or poor insulation quality can lead to stator failure and should be monitored regularly to prevent a shortened life of the electric motor stator. Stator analysis using EMAX technology is performed by evaluating the phase relationship of voltage and current for each of the three phases of an AC induction motor.

AIR GAP

The Air Gap fault zone describes the measurable distance between the rotor and stator within the motor. If this distance is not equal throughout the entire circumference air gap eccentricity occurs. The varying magnetic flux within the air gap creates imbalances in the current flow, which can be identified in the current spectrum.

Eccentricity analysis using the MCE® Rotor Influence Check (RIC) test is most successfully applied in troubleshooting if pre-existing data is available so that trends can be observed. Eccentricity analysis using EMAX technology is performed through a high-frequency spectrum of the current signal. If the number of rotor bars and the speed are known, the MCEGold® software automatically places an (X) at the four peak locations which identifies eccentricity.