SERVICES

Reliability Centered Maintenance Programs

Services

What are Reliability Centered Maintenance Programs?

Reliability-centered maintenance (RCM) or Condition-based maintenance (CBM) is an approach to maintenance that uses the data from Predictive Maintenance evaluations to help plan and prioritize interventions, decide on future equipment purchases, redesign equipment or processes, and many more things.

It is an approach that combines purchasing, engineering, maintenance, and operations to view the creation of your product with the most reliable items and actions to achieve the lowest cost of production for the entire process. This type of approach makes the entire company a team to balance the needs of each department to contribute to the bottom line.

Outside of an RCM approach, buying the cheapest bearing might be good from the Purchasing Dept’s point of view if they only are acting to “lower costs”. But if low-quality bearings double maintenance over time, and use 3 times as many bearings in the same timeframe while lowering production throughput, then any net savings from Purchasing are destroyed by the exponential cost overruns from Maintenance & Operations. Many companies suffer bankruptcy or move overseas because top management demanded that all departments cut costs without looking at the overall effects such an order can create.

Why Reliability Centered Maintenance Programs are best for Preventive Maintenance

The goal of an RCM (reliability centered maintenance) maintenance strategies is to increase productivity and profits by avoiding unplanned downtime and sudden equipment failures that streamline throughput for the most profitable product.

This approach is not limited to just manufacturing. For example, wastewater does not “sell” a product. But unplanned failures can allow untreated

sewage to be discharged into fresh bodies of water. The fines for such a discharge can be large and ruin a budget.

The benefits from an RCM approach are determined by how expensive unplanned downtime is to the entity.

Knowing how to implement a Reliability Centered Maintenance Program and having the correct PdM assessment tools, allows you to begin recapturing lost time and money.

What is Predictive Maintenance?

Condition Monitoring or Predictive maintenance is monitoring the health of a machine before it breaks by using hi-tech tools to determine if a machine is losing efficiency or entering a failure mode.

Predictive Maintenance Overview

Predictive Maintenance Strategy (PdM) uses high-tech diagnostic tools to detect if an asset is entering a failure mode or losing efficiency. These tools find faults and help to predict that a failure is approaching. Just as a medical test can tell if a person is developing a disease, PdM tools help you to find if problems are developing in your equipment.

It is called Predictive Maintenance (PdM) when you are monitoring and trending the condition of your equipment using these high-the diagnostic tools.

The monitoring of the trend of an asset helps to predict when the best time to render maintenance actions would be. These actions are usually less costly in terms of collateral damage, parts, downtime, and man hours.

After a company installs its equipment the job is thought to be done. The equipment is supposed to run for its life cycle and wears out after a long period of time. Most maintenance departments are set up to operate in a “run-to-failure” mode. This is really saying they have no idea when something will break down until it is obvious the asset is having a problem or it just stops working.

Proven Results for Predictive Maintenance Programs

Several industries have been studied to find out what the pattern of failure looks like. It has not surprised maintenance managers that the majority of failure occurs from random events with age-related failures creating only 11% of the total number of failures. These curves have been found in the paper industry, airlines, and the US Navy and a wide variety of industries continue to exhibit the same patterns of failure.

Several industries have a great history of using Preventative Maintenance tasks and procedures. But this is a time-based approach that can violate the maxim “if it ain’t broke, don’t fix it”. But additionally, PM does not have a way to discover when failure is imminent due to a random event, an infantile part failure, an installation that was not within spec, or another non-time-based approach.

Having the knowledge of how healthy or ill your machines are, places you in control over planning when the best time to repair or replace components. PDM can help on a production line in a manufacturing environment, a wastewater treatment plant, in a power plant, a mine, or a bakery to name some examples.

Just like a doctor checks your blood pressure, temperature, lung sounds, etc, maintenance personnel can use PdM tools to collect valuable information about the health of your machines, both at installation and farther along in time.

Repairs take less time and money compared to the replacement of failed equipment.

Potential ROI of a Solid RCM Process

At Failure Prevention Associates, we offer tool systems, implementation consulting, training, and condition monitoring services as an approach to improving profitability, reliability, efficiency, and improved safety to critical or industrial processes and manufacturing.

Having the early knowledge of which critical assets need maintenance actions, gives you time to plan the repair, order, and kit together the parts for the fastest, safest & error-free turnaround. Real maintenance is intervening before the asset fails. Waiting for things to go boom on their own is just failing to maintain.

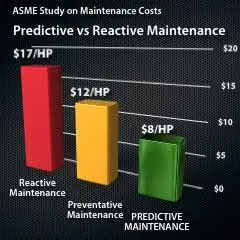

According to an ASME study, Reactive Maintenance costs on average $17.00 per HP. Preventative Maintenance gives you a lower cost at $12.00 per HP. However, the lowest cost by 33% is Predictive Maintenance at $8.00 per HP.

Proper RCM analysis will discover which piece of equipment is having trouble weeks, months, or years before it is obviously failing saves money & time but more importantly knowing what asset needs repair places you in control of your equipment.

How Failure Prevention creates Reliability Centered Maintenance Programs

Predictive Maintenance and Condition-based monitoring tools turn most maintenance actions into simple repairs versus what happens when the entire machine fails and collateral damage occurs. Massive failures routinely cost 3 to 20 times more than a planned repair since you now have lost production profits, operator time costs, and collateral damage added to the failure. And let’s not forget Mr. Murphy, he will make sure overtime costs are high since many machines seem to fail after 3 pm on Fridays, Holidays, and weekends.

Repeated failures of the same equipment are also an area to address with condition monitoring. We help solve problems that are costing you money. Using vibration analysis, thermal imaging, lubricating oil analysis, ultrasonics, and motor current analysis can help pinpoint the root cause behind repeated failures. Eliminating repeated failures drive profitability and reliability exponentially higher.

The return on investment for a relatively small amount of predictive maintenance services and tool systems can be huge. Not only on savings of machine downtime but also in optimizing your machine throughput.